Advantages

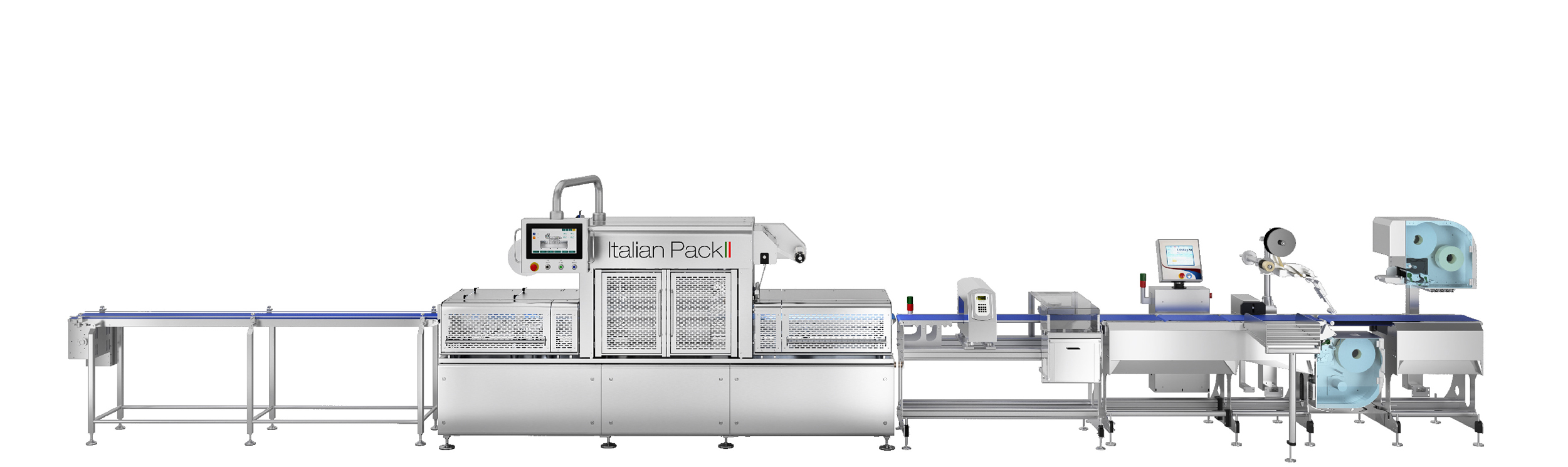

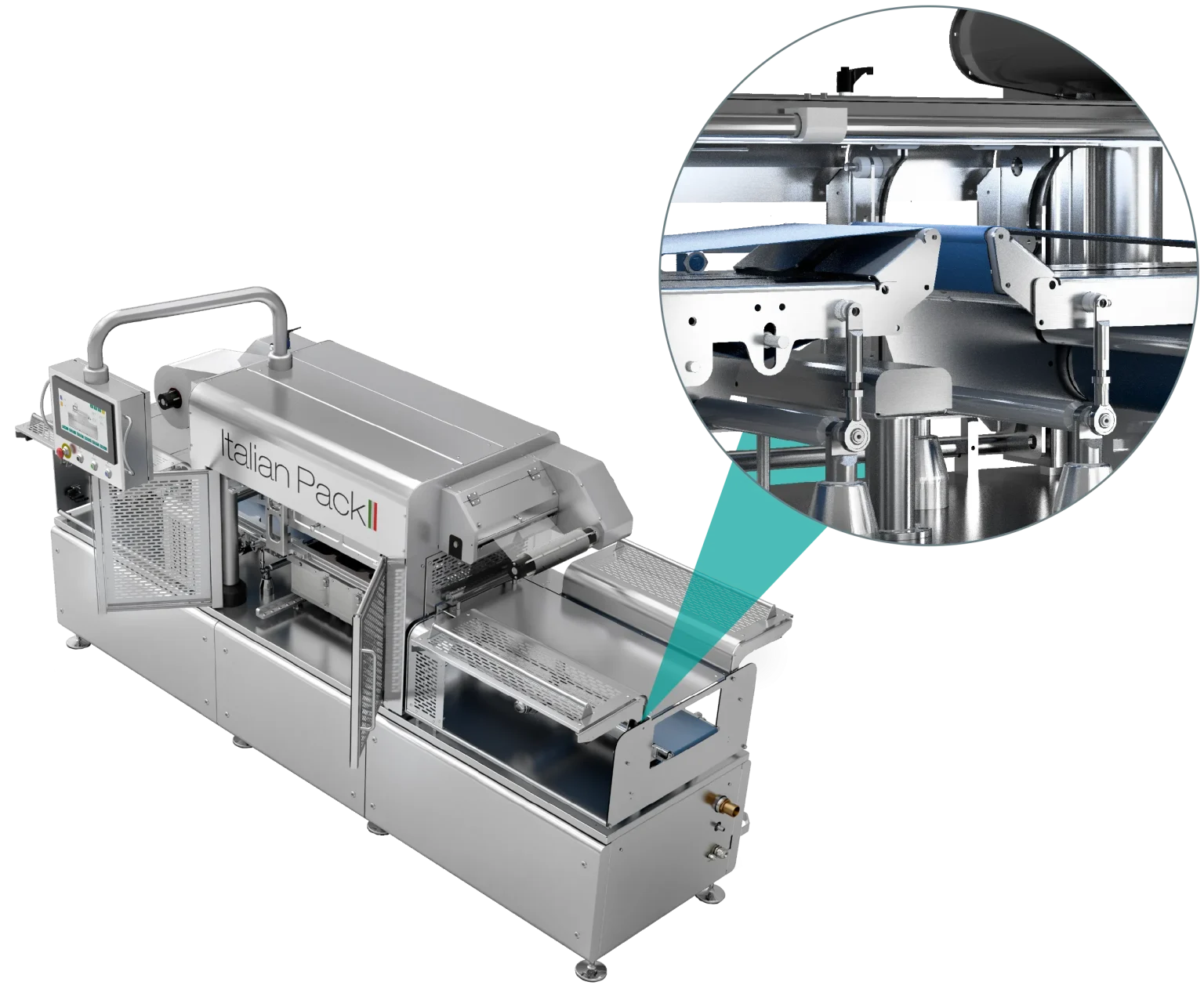

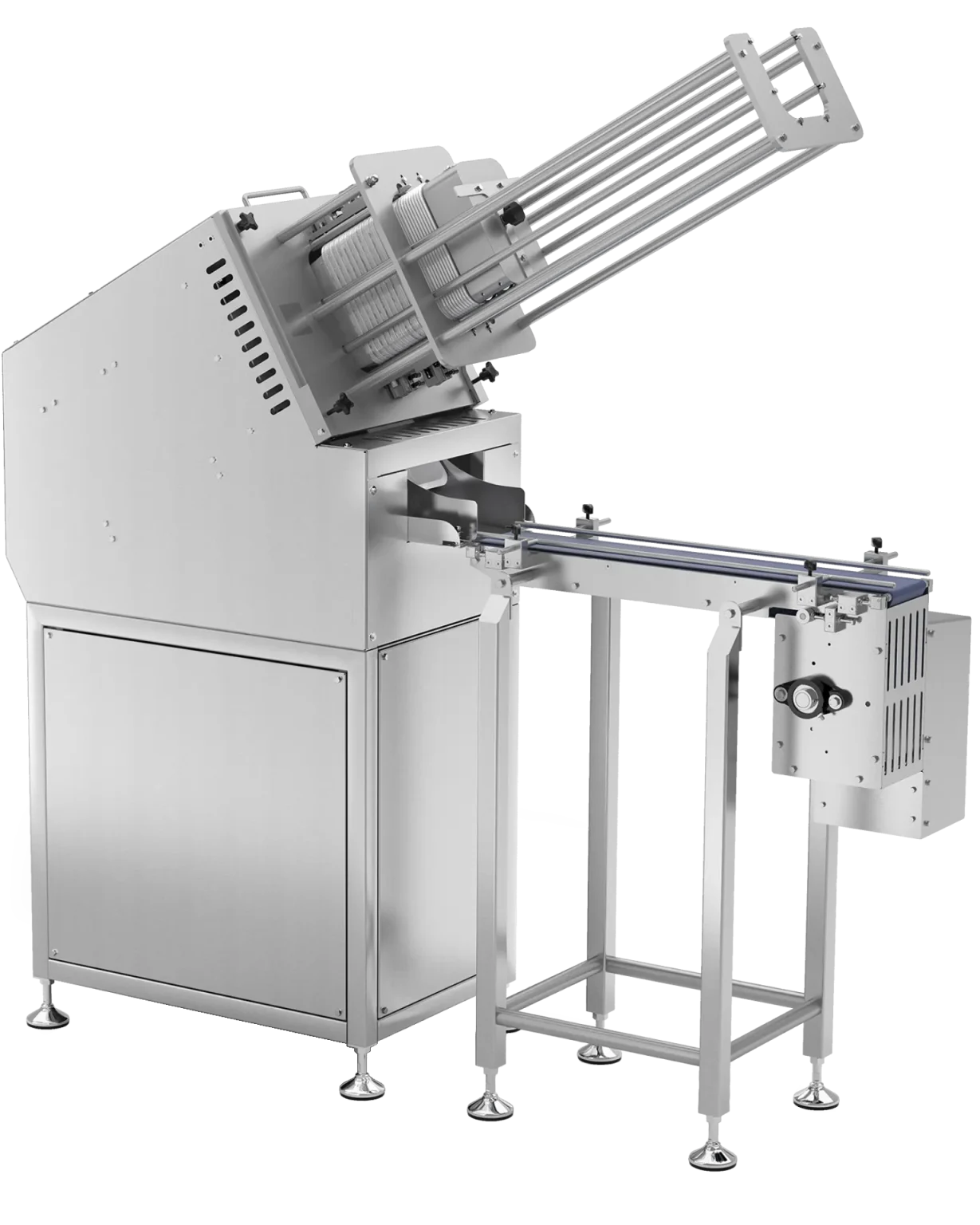

After more than thirty years of designing, developing and improving heat sealers that have met the needs of various manufacturing companies (from gastronomy to small-scale manufacturers, large retailers, industry, catering), Italianpack demonstrates its professional maturity with the new ARGO, a fully automatic in-line packaging machine.

The result of long-standing experience has led to the creation of this new range of packaging machines, which combines the consolidated response to the needs of the various food categories (meat, fish products, pasta, confectionery, fruit and vegetables, dairy products, ready-to-serve meals, etc.) in a single machine.

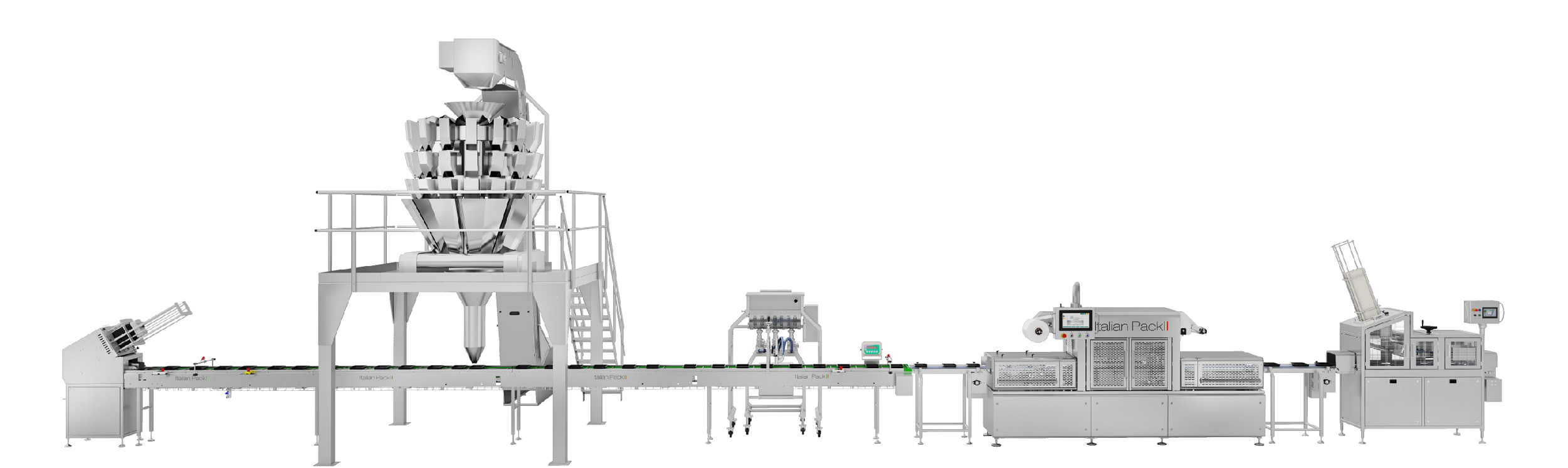

The in-line handling of the packages by means of arms makes ARGO suitable for the development of complete and automated packaging lines. Italianpack, also thanks to the new ARGO, is able to offer solutions that include tray destacking, product filling (whether solid or liquid), package weight control (before and after closing the tray), film marking, closure of the tray with neutral or pre-printed film, application of lids on the trays, sensors for detecting foreign bodies

in the packages.

ARGO can also be integrated into existing lines, interfacing with external machinery and thus optimising its performance.

Continuous efforts and continuous research have led Italianpack to innovate technologically. As a result, ARGO has been designed to be controlled electrically.

The pneumatic drives have been replaced by electric actuators

(8 brushless servomotors), which optimise the energy used while maximising efficiency.

Thanks to the continuous development of innovative solutions, which have enabled Argo to be equipped with Brushless servo motors, a new generation of vacuum and gas intake system, we have been able to achieve a productivity of up to 25 cycles per minute in sealing mode, up to 18 cycles per minute in MAP mode and up to 10 cycles per minute in SKIN mode.

The strength of ARGO, like all Italianpack packaging machines, is flexibility and the ability to adapt to different manufacturing conditions

while ensuring high packaging standards. In this sense, all the packaging technologies can be controlled with a single packaging machine and a single die:

sealing only, vacuum packing, gas flush, modified atmosphere packaging, Skin, protrusion Skin and stretch.

High Quality

Precision, Power, High performance

The machine is equipped with 8 brushless servomotors, which guarantee high efficiency and absolute precision in its operation.

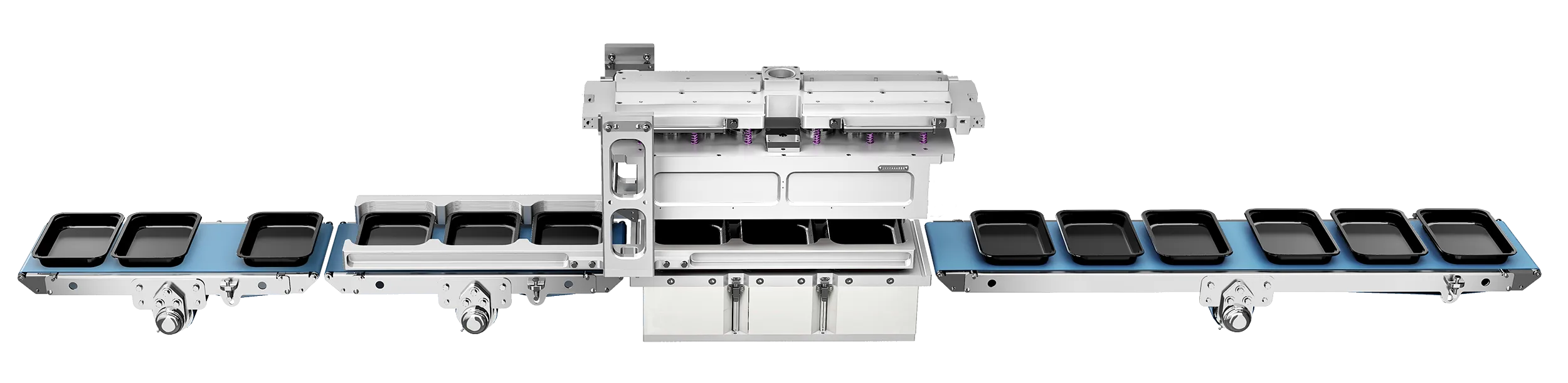

Handling welding bell

The rise and fall of the welding bell is carried out by a worm screw controlled by a servo Bruschless motor, in addition to the speed and a high and constant pressure, we have a total flexibility to every change format being able to adjust the height of the bell through program. In addition, the worm screw is equipped with an automatic greaser.

Technologies

New UI TouchScreen fitted on an adjustable arm

Touch wide screen 15” 1.8 million colors, USB/ Etehernet ports, 10000 preset programs, unlimited custom programs, language customizations. Integrated temperature control, advanced MAP paramatri management, Tray SKIN , VAC. In addition, our touch Wide Screen has the function, SWIPE PAGE; ZOOM and the possibility to insert VIDEO, PDF.

Teleservice

Consapevoli dell’importanza di ridurre al minimo i fermi produzione ARGO è equipaggiata con un modem e una porta Ethernet integrata per il collegamento ADSL, permettendo quindi un tempestivo servizio di teleassistenza e di monitoraggio della confezionatrice anche in caso questa si trovasse in luoghi difficilmente raggiungibili. ARGO è inoltre progettata per rispondere ai requisiti dell’INDUSTRIA 4.0

Easy cleaning

Argo has been designed to meet all the hygiene requirements of the food industry. Thanks to the materials used, the tray handling arms positioned at the top, the possibility to open the conveyors of the line and make them suspended and have a plan compleationally accessible for washing and sanitizing, our line is completely accessible and washable.

Assisted tool change software

Easy access

Sealing, vacuum units and electronic instantly accessible via front panel for quick and easy maintenance and cleaning operations.

Motorized infeed conveyor

Control of the transport of the trays through 2 motorized conveyors controlled by 2 independent servomotors BRUSCHLESS which spaced the trays correctly and quickly.

Motorized Outfeed Conveyor

Motorized conveyor output that allows to transfer in a constant and precise way the trays in the end of the machine line.

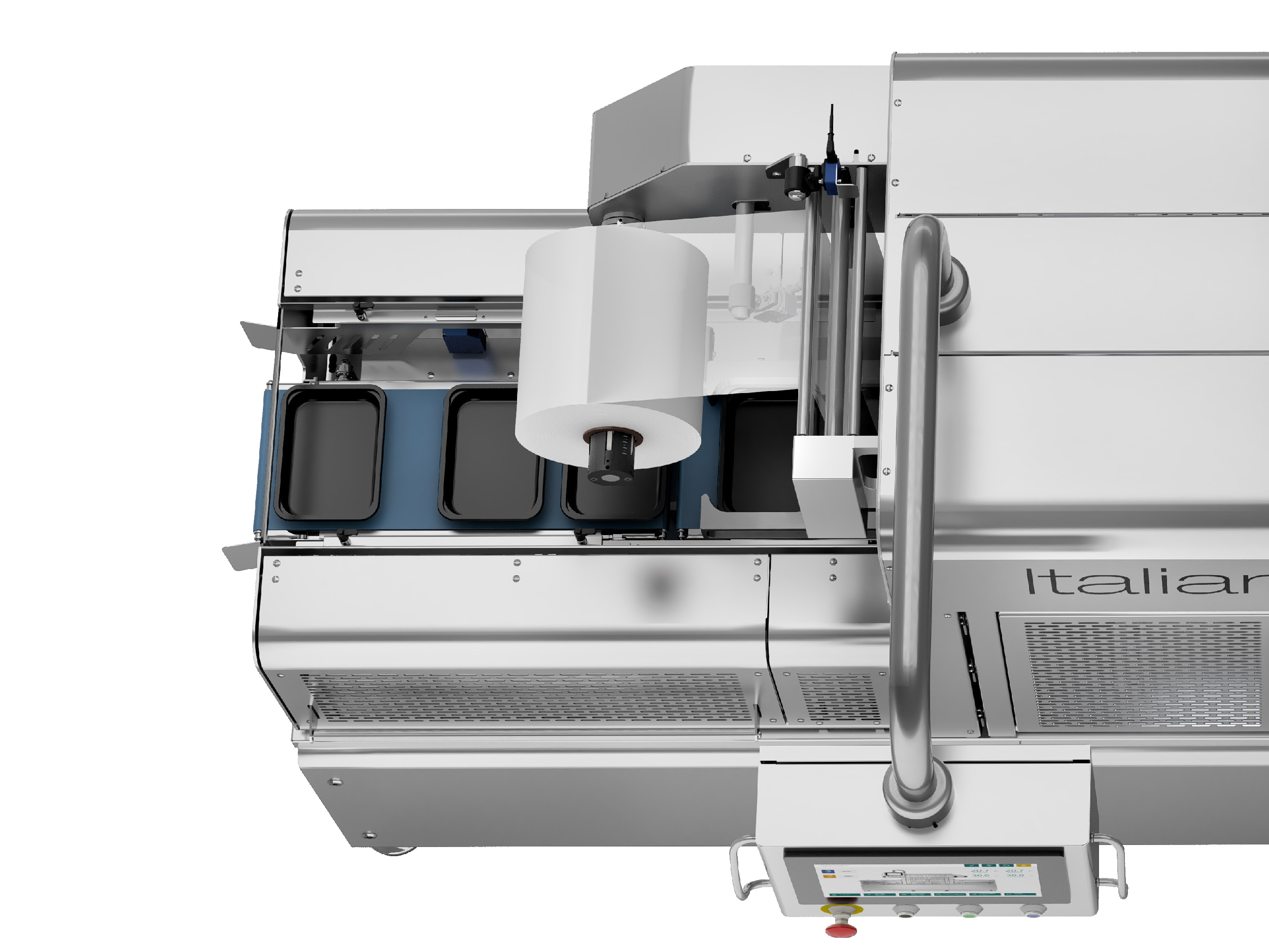

Film coil shaft driven by brushles motor

Expanding shaft

Film waste rewinding by brushless motor

Thanks to the triple motorization through Bruschless servo motors with the automatic regulation of the film tension, we can use films with microns and smaller and smaller rejects with a view to increasingly important sustainability and speed up the productivity of the cycle.

Connection

Vac: Vacuum connection (pipe Armorvin internal diameter ø50).

Gas:Gas connection (pipe internal diameter ø16).

Air: Pneumatic supply position (øi pipe Elastolan ø12).

Power:Electrical supply position 400V 3P+N+PE.

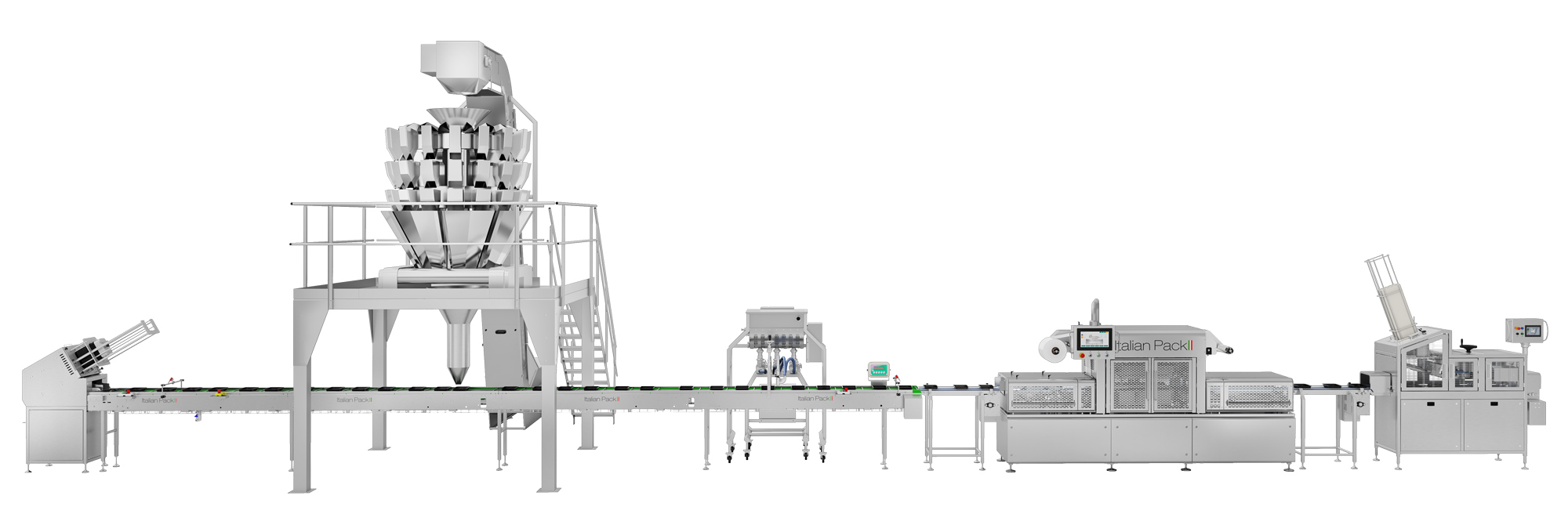

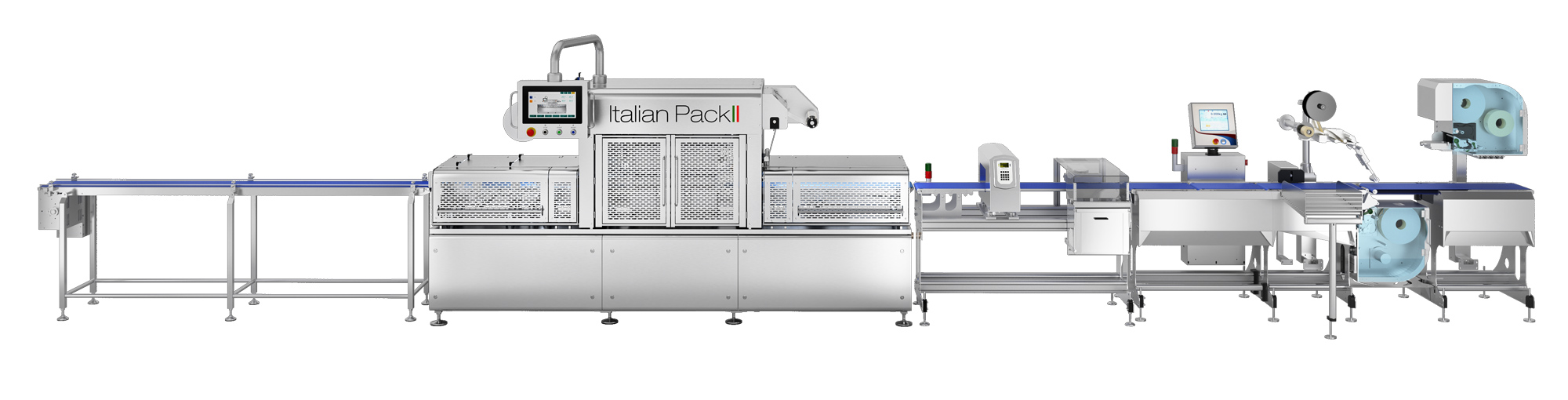

/// Special lines ///

-

DEN35

Denester

- Conveyor

- Filling units

- Argo 720

-

LID30

Automatic lid applier

- Conveyor

- Metal detector

- Electronical weigher

- Lower labelling machine

- Upper labelling machine

Accessories

Denester

Italianpack, with its long-standing experience gained in 30 years of business, has focused on the development of an AUTOMATIC DENESTER. The main purpose of this solution is to support the trends of the sector in which it operates, aiming at increasingly complete automation of the packaging lines.

Automatic lid applier

Italianpack, a leading company in the production of traysealing machines, is pleased to present its new AUTOMATIC LID30 LID APPLIER.