Technologies

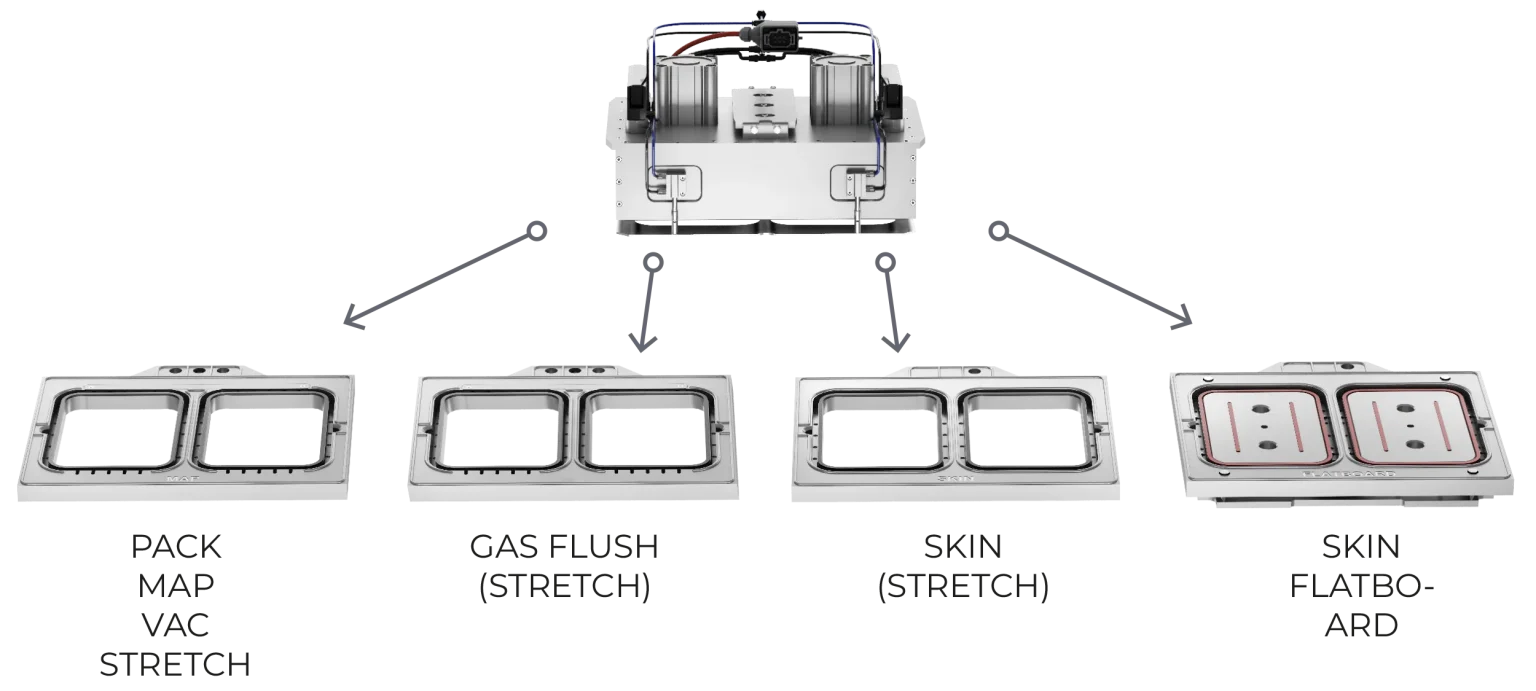

1 Tool - 7 Technologies

Thanks to the specially designed Trays Holder

Easy Die- change

Tool-less mould changing

Electric box and Touch screen

Electrical panel with numbered contacts, easily accessible and sanitizable.

7” color TOUCH SCREEN for a simplified program visualization and management, history chronology visualization and storage of all machines alarms.

PLC with USB port, 99 programs memory that allows for easy management of the different recipes: sealing only, partial or full vacuum, gradual vacuum and Vacuum-gas (MAP) values controlled via the digital vacuum controller within the PLC. It also permits to manage all the optional features and options available with the machine.

Visual alarm display and incorporated diagnostic page.

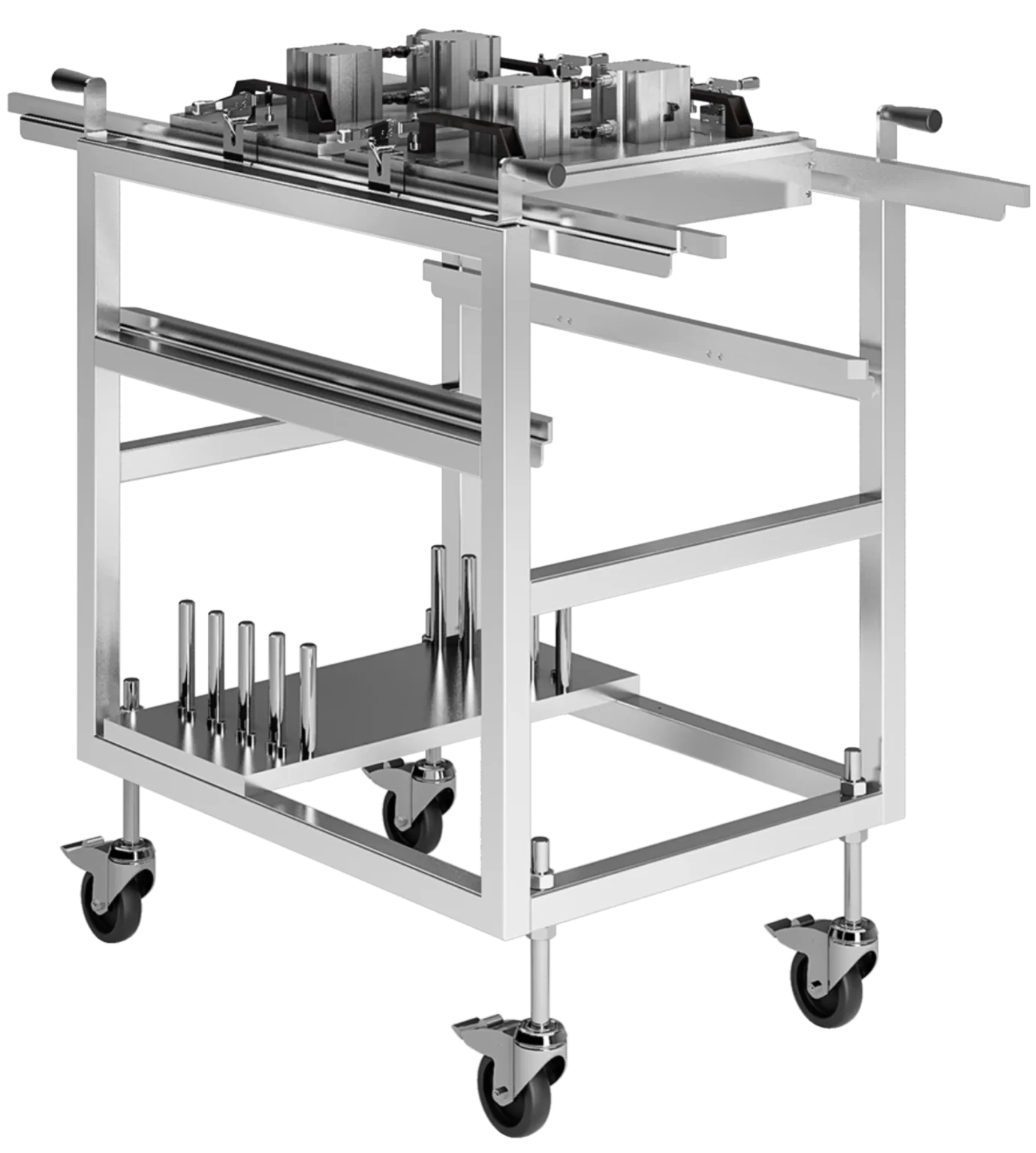

Die-Change Trolley

Stainless steel trolley for easy, tool-less mould-change for maximum safety

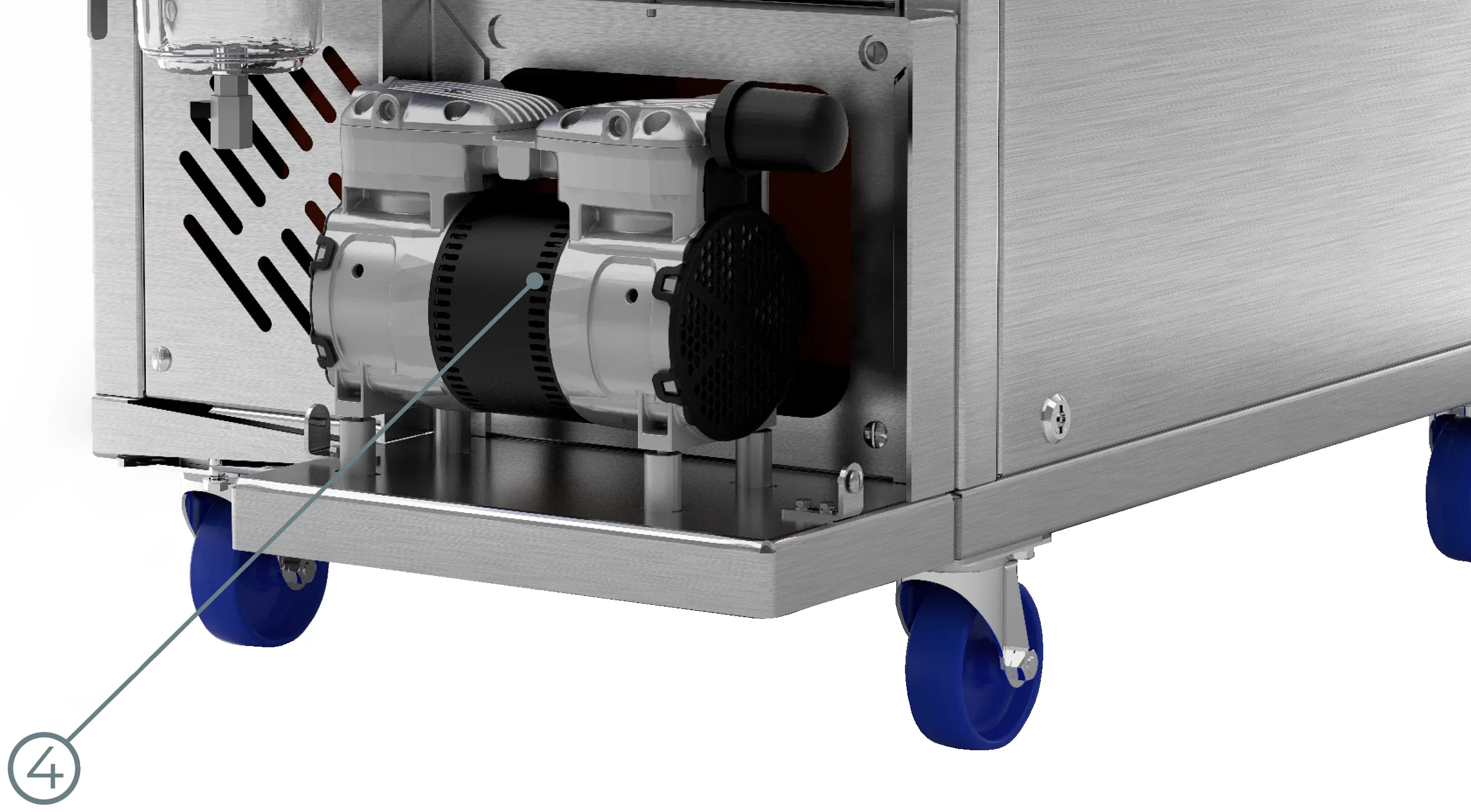

Busch Pump

Integrated Busch vacuum pump standard system 63/100 m³/h

Busch Pump

Busch vacuum pump oxygen system 63/100 m³/h pumps suitable for high-oxygen packaging percentage (>21% oxygen).

Automatic Film Rewinder

Automatic film rewinder with programmable film advance for significant film waste reduction. OPTIONAL Printed film centering device also available.

Pre Heating

Aluminium plate with Teflon coating.

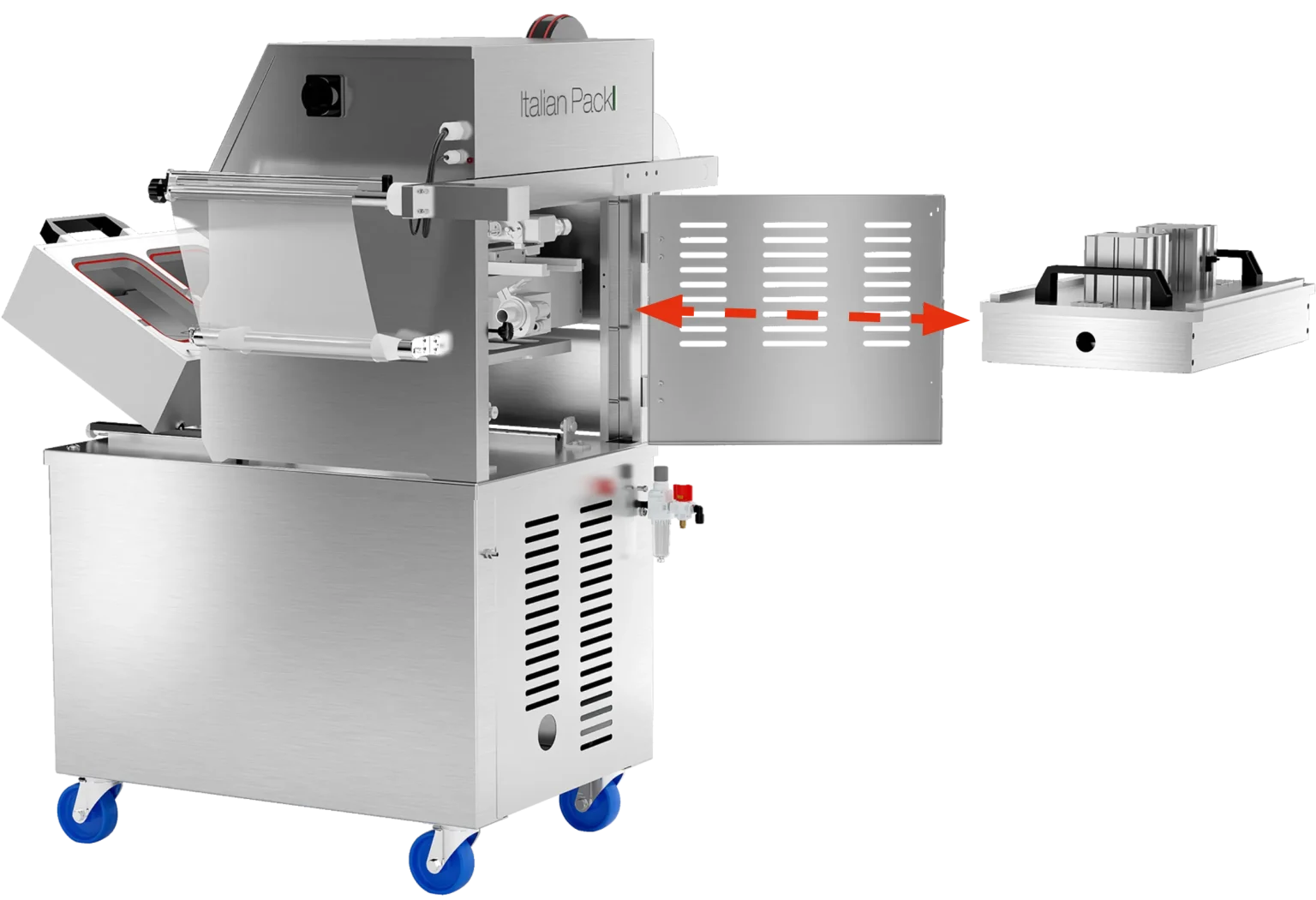

Removable Bottom Vacuum Chamber

Tool-less vacuum chamber removal ensures high standards of hygiene and cleanliness.

Modular Drawer

Teleservice

Possibility of ADSL connection through integrated Ethernet port for a teleservice that permits to supervise in real time the machine state from anywhere, allowing prompt interventions and clearer communications with a consequent saving of costs owing to travel expenses and production standstill.

Optional: possibility of modem connection with sim card.

Oceania retail

When food packaging becomes an internal process at the points of sale of large-scale retailers, it takes on a role of crucial importance for the enhancement of the product itself.

With the experience gained in over 35 years in the packaging industry, Italian Pack has decided to develop specific tray sealer for large-scale retail, in order to assist its partners in the store for the optimisation of time and resources, limiting waste and guaranteeing high-quality packaging even for the most demanding customers.

Oceania Retail, the new born at Italian Pack, is a natural evolution dedicated to large-scale retail of the already

well-known Oceania machine, including all the latest technologies for packaging food products; it is supported by the most advanced software to ensure simplified work program control and thus have the possibility of configuring the machine as required by the store, starting with the type of packaging. With the same machine and a suitably configured mould, it is possible to package the products in skin, MAP, smart gas, gas flush and sealing mode.

The recommended fields of application of Oceania Retail are the following: Butchery and delicatessen, fishmonger, dairy products, fruit and vegetables, gastronomy, bakery.

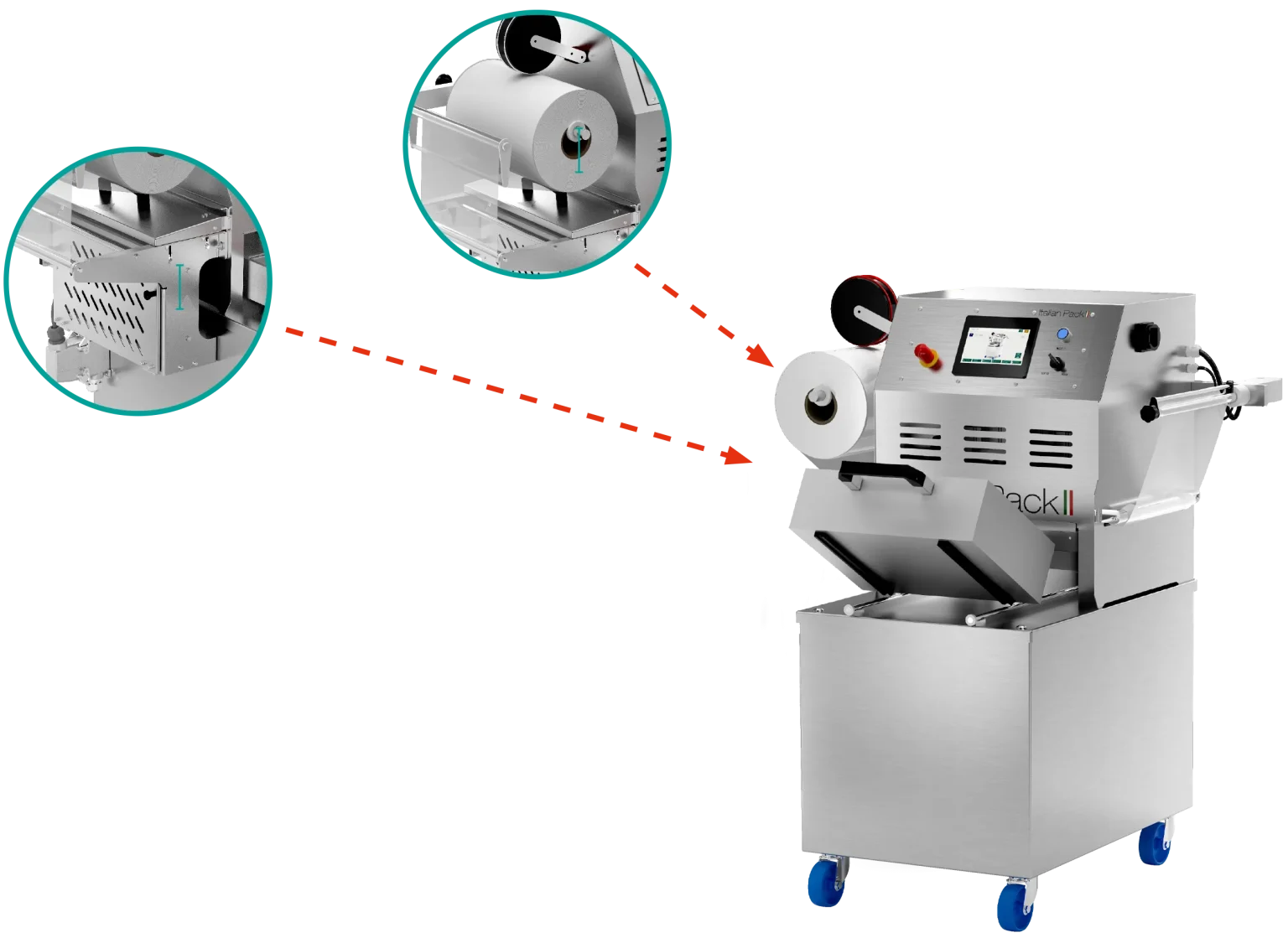

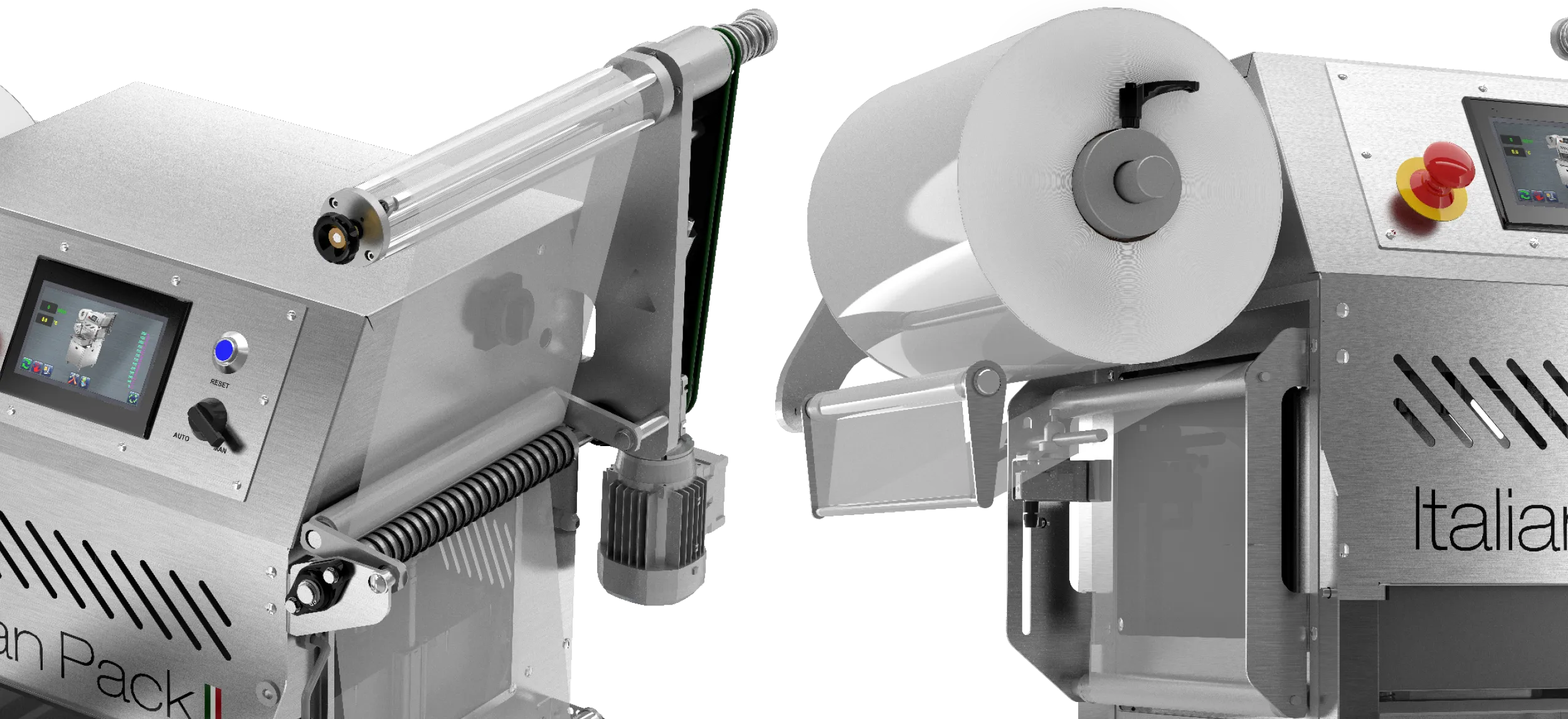

The ability to use the same machine with different tray formats is certainly one of the strengths of Oceania Retail, thanks to the fast frontal mould changeover, very simple and intuitive; the positioning of the film reel is facilitated by the millimetric ruler placed near it.

It is also possible to package products with recyclable materials, reducing waste and limiting the environmental impact.

The compact structure and the swivel wheels enable it to be moved easily and safely, positioning in the most functional way within the store.

Oceania Retail can be configured with various optional features according to the desired packaging requirements, which make it even more versatile.

Quick tool changing system

Tool-less mould changing, optimzed for in the in-store packaging

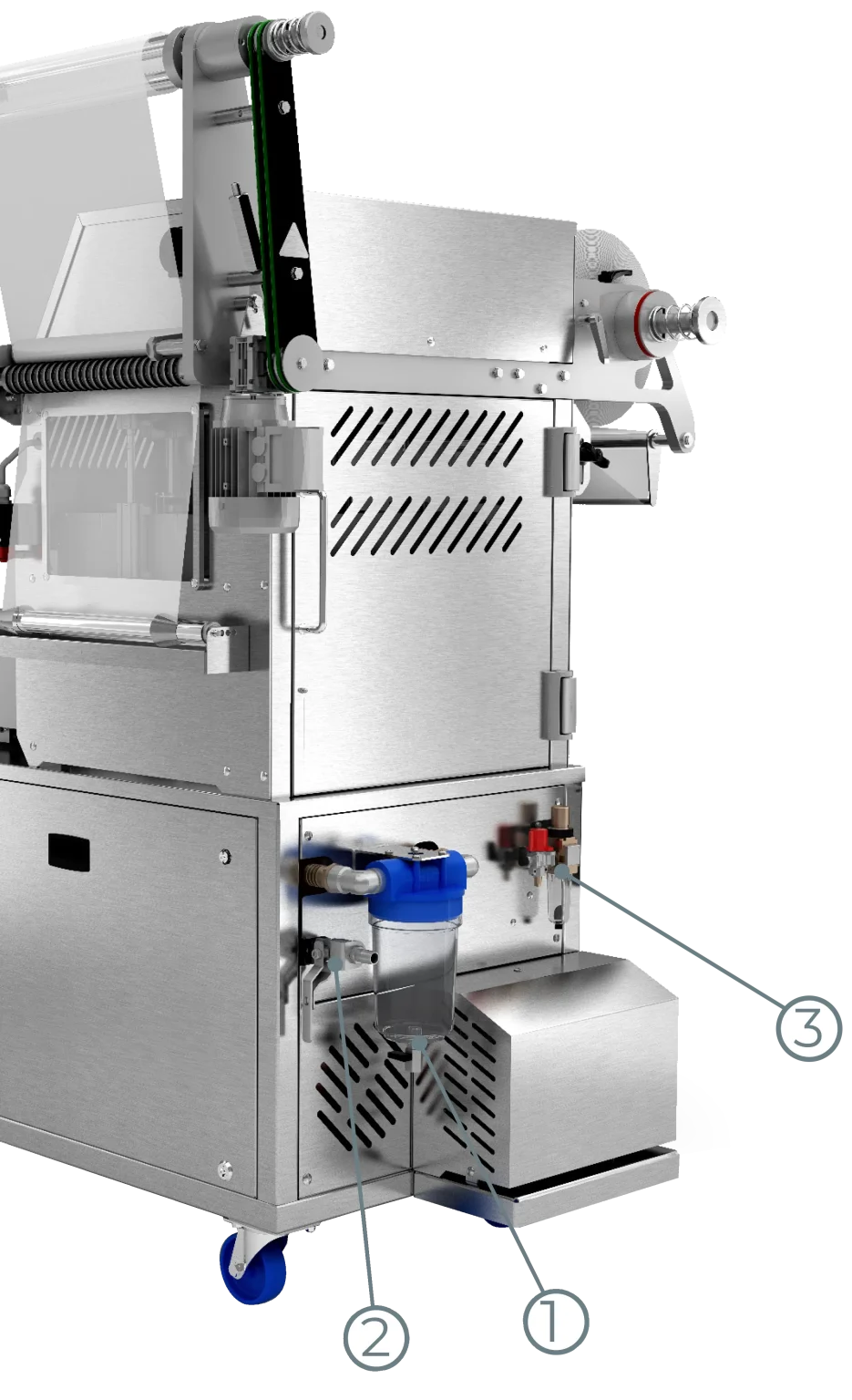

Easy access

Easy sanitization and cleaning operations thanks to openable protections that permit a direct access to the internal zones, guaranteeing safety.

Simple access to

1. Electrovalves manifold 3. Vacuum valves for Skin and/or Vac packaging mode (standard)

2. Air compressor tank

Automatic film unwinding and rewinding system

Supporto di svolgimento film removibile per consentire alla macchina di passare anche attraverso porte della larghezza di 850 mm. Optional: kit centratura film stampato. Riga millimetrica per verificare la posizione corretta del film accanto al rullo di ingresso e per verificare la corretta posizione dei coni accanto al rullo di uscita. Riavvolgimento automatico dello sfrido.

Additional components & facilities

2. Gas intake lockable valve

3. Compressed air inlet filter

1. Liquid Filter

Additional components & facilities

1. Liquid Filter