characteristics

- Machine with full stainless steel conception.

- Control Panel on telescoping arm.

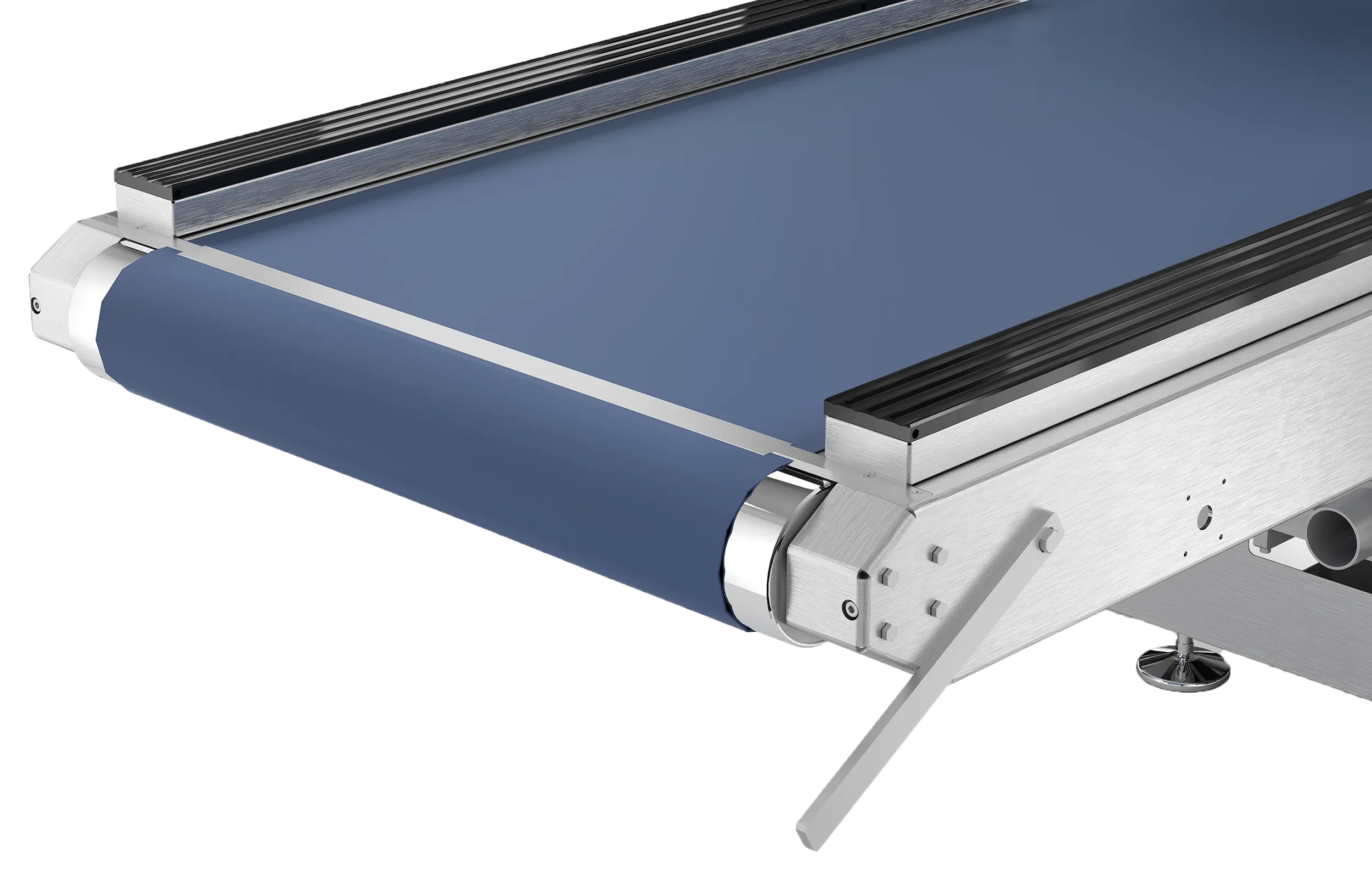

- Stainless steel chamber HEAVY-DUTY with automatic transport belt.

- Double aspiration pipe.

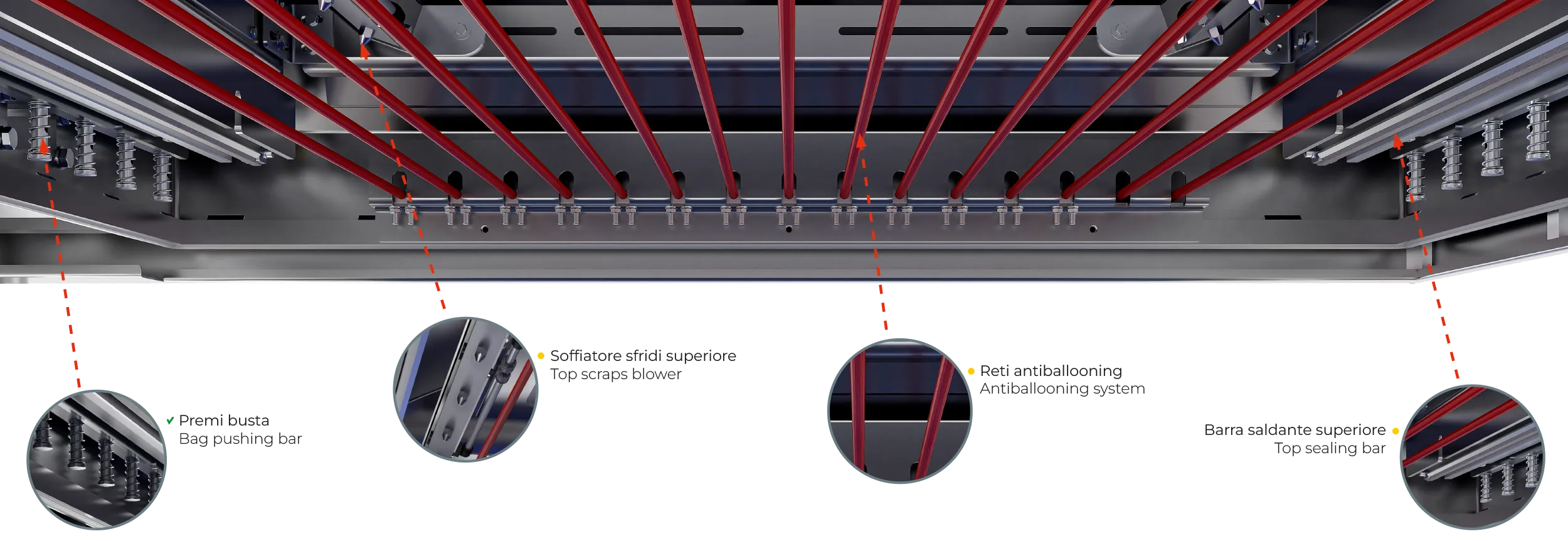

- Every sealing bar of 1000mm is double with independent sealing

- Stainless steel lid.

- Suitable for a large range of product and dimensions.

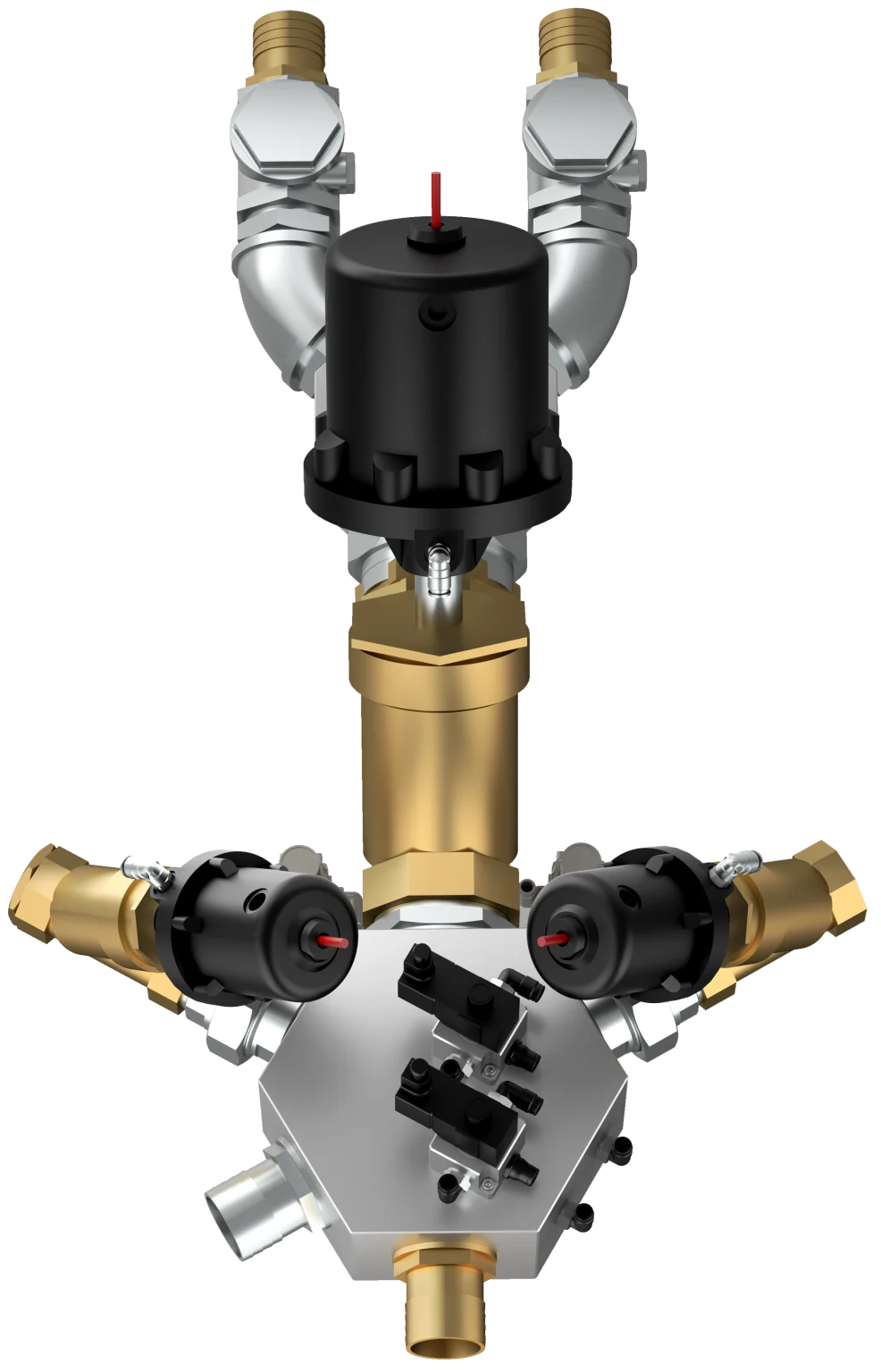

- Lubricated high vacuum pump Busch: 300 m3/h (standard configuration), 600 m3/h ROOTS pump (optional configuration).

- Large touchsreen, intuitive graphical interface.

- 99 programs adjustable in % and mbar /hPa.

- Access security program.

- Digital control of the times of vacuum and sealing.

- Stop button to partial / full cycle interruption.

- Automatic notification to restore oil.

- Voltages available to countries outside the EEC.

- Cut-off seal (optional).

- Scraps aspirator (bin + accessories) (optional) Busch model PHENIX SR 0400 C.

- Conveyor quick releasing system (optional).

- Product holding system (optional).

- Transverse slat conveyor (optional).

- CE marking (machine conformed to Machines Directive 2006/42/EC, Low Voltage Directive 2006/95/EC, Electromagnetic Compatibility Directive 2004/108/EC)

- 7.2” PLC Touch screen, 65,000 display colors

Read more

Technologies

Scraps collettor

PLC Touch Screen Control Panel

7.2” PLC Touch screen, 65,000 display colors, USB port/Ethernet, 99 packaging programs, language selection, integrated temperature control, menu-driven vacuum parameters.

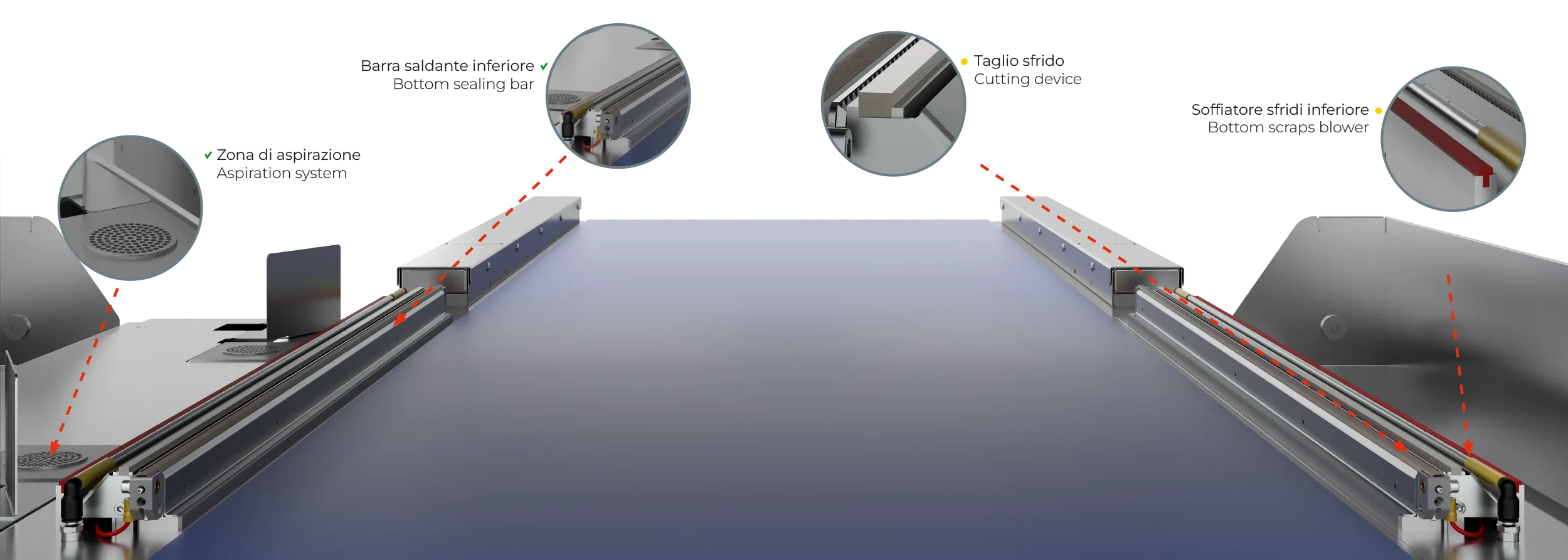

Chamber

Stainless steel chamber with round shape for easy cleaning

Vacuum circuit

Convyeor

Automatic infeed conveyor

Unblock convyeor

Unblock convyeor system for easy cleaning

Scraps aspirator

Transverse slat conveyor